NEW EQUIPMENT

TO OPTIMIZE YOUR REASSEMBLIES

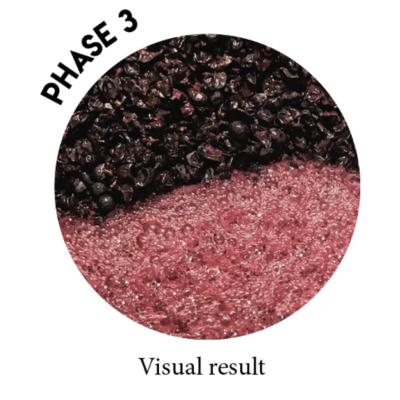

The solution makes it possible to manage the quality and efficiency of pumping-over activities during the winemaking period.

It was design and developed at the request of Bordeaux winegrowers and oenologists and is based on Clairéo's experience in injecting air into wine liquids and on a patent that has been in the public domain since 1962.

The equipment

What are the components ?

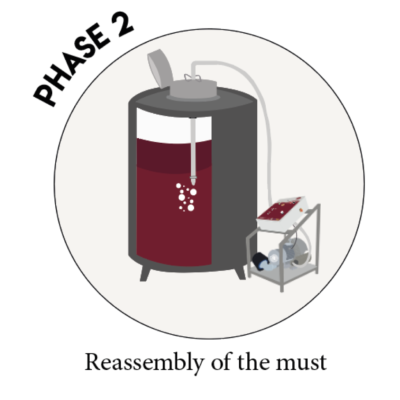

The equipment consists of a blower that can be fixed on a base, on a piece of furniture or on a wall as well as a stainless steel rod that can vary in length from 2 metres to 3.50 metres, depending on the depth of the vats. At the end of the pipe, immersed in the tank, is a nozzle that diffuses large air bubbles or CO2 from the fermenting must. The nozzle fixed on the rod is removable, different types of diffusing nozzles are available with orifice sizes varying according to the desired pressure.

Examples of locations

Air-Vinif in Kit - Ready to be fixed in a vat (stainless steel base supplied)

Air-Vinif on a support - Amphora